Fire compliance

Fire compliance is a very broad subject which ranges from simple premises fire risk assessments to reverse engineering of highly fire engineered buildings. Our team comprises several fire engineers and fire risk management professionals. Our key services in this category include:

This is a fire engineering process laid out in BS 7974:2019 Application of fire safety engineering principles to the design of buildings – code of practice. Where fire safety engineering is defined as “application of scientific and engineering principles to the protection of people property and environment from fire”, BS 7974:2019, section 3.17.

There are several sub systems identified in BS 7974:2019, these include:

- Sub-system 1 – Initiation and development of fire with the enclosure of fire origin

- Sub-system 2 – Spread of smoke and toxic gases within and beyond the enclosure of fire origin

- Sub-system 3 – Structural response and fire spread beyond the enclosure of fire origin

- Sub-system 4 – Detection of fire and activation of fire protection systems

- Sub-system 5 – Fire and rescue service intervention

- Sub-system 6 – Occupant evacuation, behaviour and condition

- Sub-system 7 – Probabilistic risk assessment

These are published as published documents under PD 7974-1 to 7.

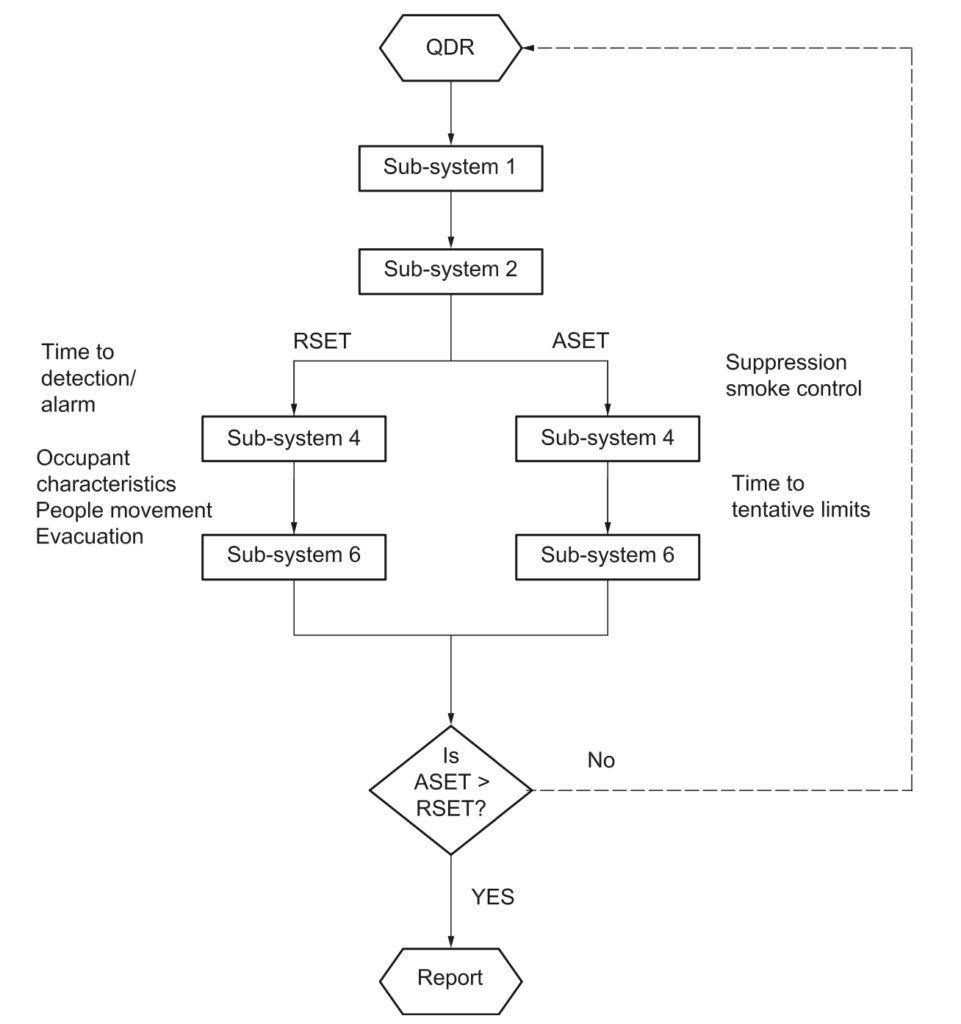

Briefly, the QDR process involves:

- Identifying the scope and objectives of the design

- Performance based criteria are established

- Design options are identified

- Evaluation of the designs using quantitative analysis. Often involving estimation of:

- ASET – Available Safe Egress Time, i.e., how much time is available for occupants to evacuation safely

- RSET – Required Safe Egress Time, i.e., how much time is required for occupants to evacuate safely

- If the performance based criteria are met, then the design is said to achieve the design objectives set at step 1.

This is summarised from the image below.

Image excerpted from BS 7974:2019, available from https://www.bsigroup.com/en-GB/

Multiple tools can be used in the QDR process to estimate ASET & RSET. These include:

- Engineering calculations for

- Fire size

- Flame height

- Speed of fire growth

- Smoke production

- Extraction systems and smoke control

- Radiant heat (risk of injury or secondary item ignition)

- Time to activation of fire detection

- Time to flashover

- Compartment temperature before, as and post flashover

- Two zone computational fire modelling

- Computational fluid dynamic modelling for smoke, temperature, products of combustion, etc.

- Computational evacuation modelling

Through our team we can support clients in full QDR assessments or sub system reviews where appropriate.

Performance of a fire safety design is typically established using numerical calculations or through computer simulation. This is the use of engineering calculation to define a building design during a fire, as opposed to following broadly available guidance, such as in Approved Document B, BS 9999, etc.

Performance based design often uses estimates for fire parameters and human behaviour to estimate available time for evacuation and compare it to estimated required time for evacuation. I.E.

ASET vs RSET

Available Safe Evacuation Time vs Required Safe Evacuation Time

Where

ASET must always be greater than RSET to ensure safe evacuation of occupants.

This is rationale is applied for life safety fire strategies.

However performance based design can be applied to property protection fire strategies, where extremely valuable items are stored, or major business interruption can threaten the ongoing viability of a company. for example:

- Protecting a very high value storage space with oxygen reduction equipment, to reduce oxygen levels below what is required to support flame, but not be a hazard to personnel. Such a system requires very precise control parameters and equipment

- Protecting a data centre from fire by very early warning and deluge system intervention before it can spread to cause major business interruption.

- Limiting fire spread by additional compartmentation to ensure business operation is not interrupted or can be rapidly reinstated.

The Qualitative Design Review (QDR) process (include link to QDR) is a performance based approach to fire engineering.

AcufireUK Limited can support a wide range of performance bases assessments using the quantitative tools listed on this website.

Fire safety engineering is defined as “application of scientific and engineering principles to the protection of people property and environment from fire”, BS 7974:2019, section 3.17. This involves assessment of specific designs, materials, their properties, occupants, and numerous other aspects to create a bespoke assessment of design options. It is an alternative approach to achieving the functional requirements of the building regulations as published in Approved Document B or specific client requirements. Fire engineering assesses design options using first principle and recognised empirical engineering calculations to assess the performance of a design against life safety or property protection objectives. This is often called Performance Based Design and is often used as part of the Qualitative Design Review approach

In some cases reuse of buildings can be achieved through fire engineered solutions and it is often used to make reasonably practicable improvements to existing operational buildings to reduce risk.

Smoke is widely recognised as the main cause of death in many fires for several reasons:

- Visibility

- Toxic gases, liquid vapour and particles

- Inhaled hot materials

- Radiated heat

Some of the particles in smoke comprise hot unburnt fuel, which ignite when sufficient oxygen is provided. Such as when hot smoke escapes from a window in a compartment fire. Thus smoke can also spread fire as moves away from its origin. The amount of smoke produced in fire varies greatly and is based primarily on the materials in combustion. Dryer seasoned wood, for example, can burn with little smoke. Plastics and low grade oils burn with very large amounts of thick black smoke, containing many toxic materials.

Based on research in the UK and US, approximately 50% of fatalities from fire occur because of inhalation of toxic particles and gases. Often this is caused because by people being unable to reach or find a place of safety or a way out, i.e. from low visibility. Which extends the time exposed to smoke.

Hence control of smoke within buildings is essential. Typically this is done by containing smoke in fire compartments, along with the fire itself. However in large buildings with extended travel distances, smoke can obscure exit routes before evacuation is complete. This sort of building can include:

- Large open plan shopping centres

- Open plan terminals, concourses, lounges, etc

- Buildings with Atria, which allow smoke to rise through multiple floors

- High rise residential buildings

Smoke control can be used to extract smoke or to pressurise sections of buildings to protect areas from smoke ingress. An example of pressurisation is found in some high rise flats, where smoke is kept from the stair core by pressurising it and pushing smoke back into the fire floor.

Smoke control systems are often labelled as fire engineered solutions. As they are often specified by a fire engineer to control smoke sufficiently to enable sufficient evacuation time.

Gases may be needed by industrial process, hospitals, factories, HVAC equipment and so on. Large volume gas storage is a specialised field and has extensive safety guidance dependent on the gas, volume stored and how it is stored.

Some gases are inert (chemically inactive and / or inflammable), others are flammable such as hydrogen and others can oxidise objects or the local environment. Oxidising agents will provide more oxygen to a potential fire and thus cause it to burn more fiercely, rapidly and release more heat, smoke, toxins, particles, etc. still other gases can be so violent that they present explosion risks, such as acetylene used in welding.

Often gases are stored under pressure. Pressurised cylinders under fire conditions heat up. Heating up gas increases internal pressure and if sufficient can lead to catastrophic failure of the pressurised container. Oxygen for example is often stored in liquid form (LOx) at below minus 118oC in specialised Vacuum Insulated Evaporator (VIE). If sufficient heat is applied to the VIE then the liquid oxygen can undergo phase change to its gaseous form, increasing its volume massively and raising pressures. Again potentially causing rupture if safety devices are overcome.

A second fire event is often defined as when fire spreads from the point of origin to another compartment, floor, building or external object. It essentially means there are now two fires instead of one.

Examples can include fire spread from:

- One flat to a neighbour

- A balcony fire to the next highest balcony

- From one floor into the building façade and up the outside of the building

- Falling debris catching nearby buildings or vehicles alight

- Car fire spread to other vehicles in a car park

- Sufficient radiated heat striking another building to catch external or items in windows alight, such as curtains or decorations.

These types of events are often mitigated using compartmentation, material selection of external fittings, location of buildings at planning stage of design and building spacing guidance.

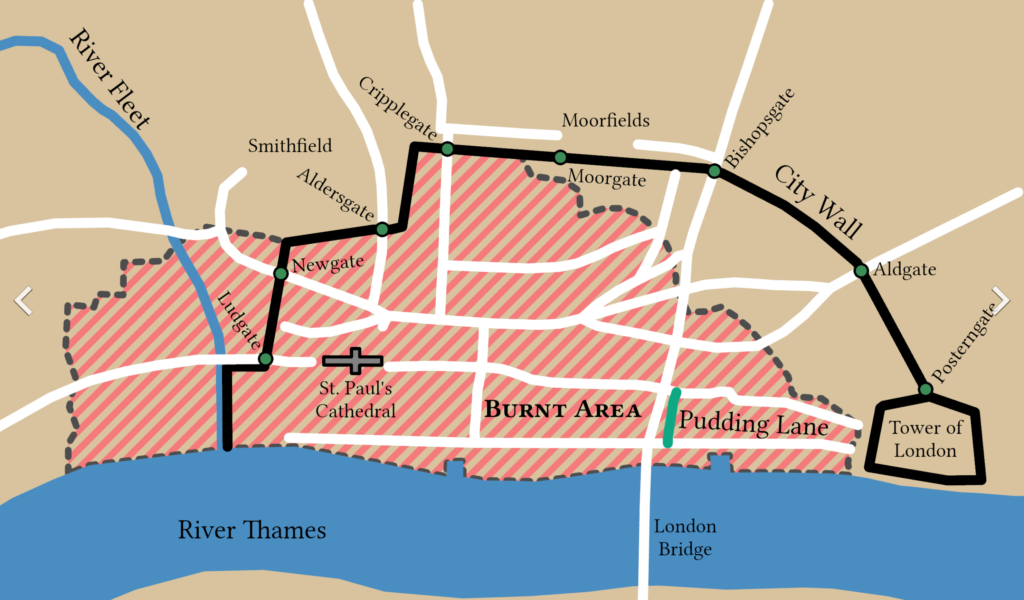

Historically this issue goes back to the largest fire event in British History, the 1666 Great Fire of London. This gutted the medieval City of London over four days but started in an simple bakery in pudding lane. Buildings were made predominantly of wood and located very close together. Fire moved building to building, even breaching the old Roman city wall. The extent of the fire is shown below:

The fire resulted in the 1666: An Act for rebuilding the Citty of London under King Charles II. It proposed construction from brick or stone against the perils of fire. it also limited the maximum number of stories and abodes.

Thus our oldest fire legislation addresses the issue of second fire events directly. However, in very high population dense buildings or areas such as towns and cities, this is an ongoing major concern. Especially with the value and need to utilise all available space.

Equally, modern construction materials are a key factor in this issue. As the cost and performance of non-flammable materials is often higher than their flammable alternatives. Most notable is the increased use of plastics since the 1970’s to their increasing using today. Many plastics are flammable, but also produce highly toxic products of combustion. This was highlighted by the 2017 Grenfell Tower fire. where flammable rain screen cladding and insulation were fitted, which allowed the fire to rise up the height of the building exterior and re-enter it on multiple floors.

This is one of the reasons why in the recent Building Safety Act 2022 (include link to this section), there are multiple powers for the HSE to enforce building material requirements on manufacturers and construction companies.

A fire can be modelled to predict its effects on heat, smoke, ability to survive and many other parameters. There are three primary methods, which are:

- Calculations using empirically proven methods or scientific first principles

- Two zone modelling

- Computational Fluid Dynamics (CFD)

Each of the three methods have their own advantages and disadvantages. But in essence the three methods have increasing levels of complexity and both two zone modelling and CFD require computing power to enable them. These two also fully utilise time, by processing many fire parameter calculations at time steps.

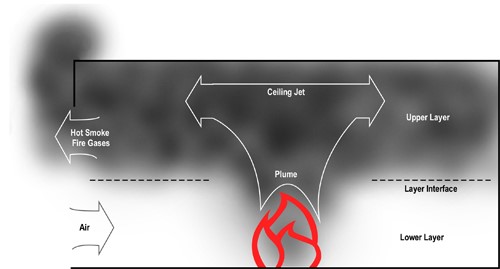

Two zone modelling is based on a broad assumption that there are two distinct zones in a fire scenario within an enclosure. An enclosure being a fire compartment, (flat, room, space, etc). The upper layer is full of hot smoke and gases whereas the lower layer is cooler and comprises of air. Both zones are assumed to be well mixed and with the only flow between them coming from the fire plume. This is summarised in the image below:

Fire growth, heat release, flame size, smoke production, layer temperatures, upper layer height, etc. are calculated on each time step of the model. This allows prediction of these parameters over time. Allowing for estimates of the Available Safe Evacuation Time (ASET). This can then be used to compare ASET to the Required Safe Evacuation Time (RSET) to get all occupants evacuated safely.

Selection of inputs are critical to the model’s accuracy and validity. Room size, fire size, heat release rate, flammable material being burnt, etc are all key to accurate prediction of ASET. Different scenarios can also be modelled, in relation to the use of sprinklers, time to activation of smoke / heat detection, triggering of smoke control systems, etc. Thus different mitigations, building designs and layouts can be modelled for their performance in a fire condition.

There are many two zone modelling tools available. AcuFireUK use the B-Risk Design fire tool produced by BRANZ . This tool also has the ability to use probabilistic input to produce statistical distribution fire assessments of the consequences of fire, rather than a simple worst case scenario.

CFD is defined as

“a science that, with the help of digital computers, produces quantitative predictions of fluid-flow phenomena based on the conservation laws (conservation of mass, momentum, and energy) governing fluid motion”, Source Fluid Mechanics (fifth edition), 2012

Where gas movement is considered a fluid-flow and the conservation of mass, momentum and energy govern all fluid flow.

CFD is can also be defined as the prediction of fluid flow, heat transfer, transfer of mass, reactions and other phenomena by solving mathematical models that govern these parameters. This is done by using partial differential equations and using the outputs to inform other equations on a time step basis. In fire simulation this is done using the Navier Stokes-equations. CFD has applications in many industries, including formula 1, biotechnology, aviation and fire modelling.

The key difference between CFD and two zone modelling is the complexity of the model. In two zone modelling there is simply a cool lower zone and a hot upper zone. In CFD there is a grid of cells created for input and output calculation. I.E., each cell affects its neighbour. Cell size is key in accuracy and validity, but also exponentially increases the amount of calculations. For example a 1m3 space, divided into 10mm3 (0.01m3) cells, results in one million cells. Thus very high computer processing power is needed for such tools. In some cases requiring rented use of online high performance computing.

CFD requires very experienced and rigorous validation use to create meaningful models. Thus full verification of input parameters is essential, as is model validation assessment and interpretation of results. Without it the results can be misleading, leading to misuse.

At AcufireUK we utilise PyroSim CFD software, which is based on open source software called FDS (Fire Dynamics Simulator), which in turn was developed by NIST in the US. As CFD are prone to misuse, all our modelling is peer reviewed internally and validate externally.

In this sense ‘guidance’ refers to legal guidance available in terms of building design to meet the functional requirements of the Building Regulations. These include documents such as:

- Approved document B

- Health Technical Memorandums (a suite of guidance covering all aspects of healthcare building and facility design)

- BS9999 Fire safety in the design management and use of buildings – code of practice

- BS9991 Fire safety in the design, management and use of residential buildings – code of practice

- Eurocodes

Such guidance documents lay out generic widely accepted ways to meet the functional requirements of the building regulations. Approved documents are defined by the Secretary of State as:

“Approved documents are approved by the Secretary of State and give practical guidance on common building situations about how to meet the requirements of the Building Regulations 2010 for England. Different approved documents give guidance on each of the technical parts of the regulations.”

In relation to fire, the approved document is Approved document B, volumes 1 & 2.

Approved documents or any generic guidance cannot cover all building designs. It is down to the building designer and developer to assess the suitability of guidance in ADB or other guidance documents. It may be required to demonstrate performance for more extreme designs. This is ever more relevant, with building designs becoming more ambitious over time.

However, most buildings in the UK are designed and built to guidance documents of one type or another. This is also the case for existing buildings, most were designed and built to available guidance at the time.

AcuFireUK provide consultancy services to support the design of buildings using guidance as well as performance based design. We also use historic guidance materials in support of retrospective fire strategy development.

As an employer or business owner, are you aware of your fire safety obligations?

The Regulatory Reform (Fire Safety) Order of 2005 states that the designated ‘responsible person’ within an organisation should conduct risk assessments to identify, manage, and reduce the risk of fire. Fire safety is therefore the direct responsibility of the employer, or business owner. No matter how big or small your organisation is, Fire Safety Orders are a legal requirement that must be adhered to in order to protect staff, together with the business premises, from fire hazards.

The role of fire compliance in the workplace

Fire poses a potential threat to any building, be it commercial or residential. Within any organisation, every employee is legally entitled to a working environment that is as safe as possible from the risk of fire, and as an employer, you are directly charged with protecting staff from such risks. Fire safety compliance addresses these key issues:

- Fire prevention plans help to keep employees as protected as reasonably possible against the dangers of fire.

- Fire drills establish good practice of what to do and where to go, in the event of a fire.

- Regular fire safety checks help to identify vulnerabilities before rectifying them.

- Regular/annual fire drills help to prepare your staff on how to safely tackle a fire with the equipment available.

- Careful preparation reduces the risk of injury.

- Ease employees’ minds with the knowledge that they are well prepared in the event of an incident occurring.

We can help you with our advanced Fire Compliance services

At Acufire we are acutely aware of all current laws and legislation relating to fire safety. We have years of hands-on experience implementing safety regulations, and have helped many different organisations in multiple industries. We can :

- Provide help and guidance regarding the installation and maintenance of safety equipment.

- Help you adhere to all of your fire compliance obligations.

- Provide consultation on fire risk assessments, reporting, and management.

Contact us today for a complete solution for all of your fire compliance services.

Fire safety encompassed by compliance

Fire safety plans include :

- Fire risk assessment

- Evacuation plans

- Fire drill practice

- Fire safety equipment training

Fire risk assessments – Regular fire risk assessments help to identify the steps that can be taken to prevent an outbreak of fire, and keep all personnel safe. Assessments should be recorded, reviewed and updated regularly. The assessment begins with the identification of fire hazards, and any individuals who may be at risk, before preparing a contingency plan and removing, or reducing, this risk whilst updating staff training.

Evacuation plan – An evacuation plan should include a detailed pictorial layout of the building, including all routes that personnel should take in the event of an incident. All emergency doors and lighting should be clearly marked, and all staff should be made aware of the escape routes and the assembly point.

Fire drills & training – All employees should be trained in fire compliance and follow current safety regulations. Any new risks introduced into the premises should be assessed, with appropriate action taken to mitigate any identified risks. All personnel should be given fire training and annual fire drills should be conducted, with all results recorded.

Fire safety equipment – Fire safety equipment that adheres with fire compliance should include :

- Fire detection and warning systems

- Fire fighting equipment

All fire detection systems and fire fighting equipment should be properly installed, tested, and maintained. Regular checks need to be carried out to ensure all equipment is working properly, and any faults should be immediately addressed. Staff should be trained to operate all of the equipment, where appropriate.